GC³ Technical Manual: Deposition

GC³ Technical Manual: Deposition

Introduction

Water is one of the Earth's most unusual features.

It is continuallydissolving or depositing solids. The phrase "depositing solids" encompasses

the scope of this chapter. These deposited solids are classified as scale

or foulants. This chapter identifies the important types of scale and

foulants, examines how the solids are deposited (mechanisms influencing

deposition) and recommends treatment of these scaling/fouling waters.

Having read this chapter, you should know:

1. The difference between scaling and fouling

2. Mechanisms and factors involved in scaling and fouling

3. Types of scales and foulants commonly found in cooling water applications

4. How to predict the scaling tendency of a water sample

5. Methods used to control scale

6. Basic scale inhibitor and dispersant chemistries

Scale Deposition Overview

The causes of scale and other fouling deposits are many, varied and

extremely complex. Investigators have studied scale and deposit mechanisms

in an effort to understand them, quantify them, and develop remedial or

preventative treatments. Deposits in cooling waters are generally classified

either as scale or as foulants, even though these deposits commonly occur

together. Scale is a hard, adherent mineral deposit that usually

precipitates from solution and grows in place. It is a crystalline

form of deposit. Foulants, on the other hand, are usually high in organics.

More often than not, they are formed from suspended solids at a point in the

system other than where they deposit. Foulants tend to be amorphous or

noncrystalline.

Cooling waters contain a large number of these potential scale- and

deposit-causing constituents. These include soluble ions (such as calcium,

magnesium, soluble silica,zinc and iron salts) that precipitate as insoluble

deposits when they encounter changes in water temperature, pH, concentration

or incompatible additives. Examples of deposits are calcium carbonate,

calcium phosphate, silica, iron hydroxides, sulfides, calcium sulfate,

magnesium salts, zinc phosphate and zinc hydroxide.

Fouling deposits can occur from natural or artificial causes. Although

these deposits are generally less adherent than mineral scale, they cause

similar problems. Examples of some of the more common natural foulants are

sand, mud, silt, clay, natural organics, dust and debris. Corrosion

by-products, process contaminants, pretreatment carryover and incompatible

chemical treatments are a few examples of artificially induced foulants.

Microbiological growth such as algae and bacteria are some of the most

common organic foulants in cooling water systems.

Scale Deposition - Mechanisms and Influencing Factors

Scale deposition, unlike other types of deposition, is a complex

crystallization process. The time it takes for an initial scale layer to

form and its subsequent rate of growth are determined by the interaction of

several rate processes (e.g., supersaturation, nucleation, diffusion,

chemical reaction and molecular arrangement of the scale crystal lattices).

Most, though not all, mineral scale-forming constituents are inversely

soluble (i.e., their solubility decreases as water temperature increases).

Therefore, when these supersaturated solutions contact heat transfer

surfaces, they precipitate solids due to their lower equilibrium solubility.

Compounds carried by water as soluble constituents may precipitate and

form scale as a result of pressure drop, temperature change, flow velocity

alterations, pH or alkalinity change or other water conditions.

Studies have shown that crystallization from solution of a material is

influenced by the following factors:

Supersaturation

A saturated solution is one that is in equilibrium

with its solute. Supersaturated solutions are solutions that contain higher

concentrations of dissolved solute than their equilibrium concentration.

When the concentrations of the scaling ions exceed their solubility product,

scaling begins. Solutions can become supersaturated by a change in

temperature. a change in pH, addition of solid seeding material, evaporation

or pressure change. Thus, if (Ca") x (CO,-') is greater than the Ks p for

CACO-, at a given temperature, calcium carbonate will precipitate

CONTROLLING PARAMETERS

Time

Temperature

pH

Pressure

Velocity

Particle Size

Other Environmental Factors

Nucleation

Nucleation, the initial formation of a precipitate can

occur for many reasons. Corrosion products, oxide films, surface

imperfection, slime masses and bacterial growths can form as nucleation

sites. The nucleation occurs rapidly at high degrees of supersaturation.

These nuclei serve as the starting point for additional crystal growth

leading to scale formation.

Contact Time

For scale to form after a solution has become

supersaturated and nucleation has occurred, there must be sufficient

contact time between the solution and the nucleating sites on the surface.

Generally, the longer the contact time, the more likely the scale formation

becomes.

Adherence

Corroding surfaces are more likely to promote scale

deposition than noncorroding surfaces. Studies using polished surfaces

indicate that microscopic roughness, whether natural or produced by

corrosion; makes subsequent scale deposits more adherent.

Crystal Growth

Although the solubility limit must be exceeded for

scale to form, the rate of scale formation is controlled by the presence

or absence of scale inhibitors and other factors. The rate of crystal growth

and the rate of inhibition of crystal growth can be studied by monitoring

the amount of inhibitor required to keep the calcium level constant during

periods when solubility limits are exceeded (i.e., during scale formation),

CONTROLLING PARAMETERS

Flow Velocity

Surface Temperatures

Bulk Temperatures

Water Composition

Molecular & Atomic Ordering

Diffusion

Other Factors

Exposure to Localized High Temperature

Because the solubility of most calcium and magnesium salts decreases with an increase in

temperature, these salts tend to form scale on heat transfer surfaces where

the metal skin temperature is greater than the bulk water temperature.

Changes in pH or Alkalinity

Changes in the pH or alkalinity of

the cooling water may also have a major effect on the solubility of scaling

ions. An increase in alkalinity decreases the solubility of calcium

carbonate and also affects the solubility of calcium and iron phosphates.

An increase in pH also decreases the solubility of most calcium salts, with

the exception of calcium sulfate.

Addition of Sulfuric Acid for pH Control

Using sulfuric acid for pH control can cause high sulfate levels and increases the probability

of calcium sulfate scaling. Hydrochloric acid should be used if calcium

sulfate is a potential problem.

Addition of Corrosion Inhibitors and/or Scale Inhibitors

High concentrations of some corrosion inhibitors and scale inhibitors may

cause deposits. Polyphosphate inhibitors, for example, may hydrolyze and

revert to orthophosphate, leading to deposition of calcium or iron phosphate.

The overfeed of some phosphonates may lead to the formation of calcium

phosphate, because phosphonates can revert to orthophosphate.

Uncommon Ion Effect

The solubility of most slightly soluble salts

can be increased by the addition of sodium chloride and nitrate ions.

This increase in solubility is known as the uncommon ion effect.

Common Types of Scale

The following is a discussion of the common types of scale. Although they

will be dealt with individually, deposits that form in cooling water systems

are rarely homogenous. Invariably, deposits consist of a mixture of

water-formed scale deposits that can act as a cement to incorporate silt

and other foulants into the overall deposit

Calcium Carbonate (CaCO3) Scale

Calcium carbonate forms a dense, extremely adherent deposit. It is by far

the most common scale problem in cooling systems. Most natural waters

contain bicarbonate alkalinity and are at a pH<8.2. At a pH>8,2, free

carbon dioxide ceases to exist. While calcium bicarbonate is soluble in

most natural waters, calcium bicarbonate will be converted to calcium

carbonate if the pH and/or the water temperature is raised. On heating, the

following reaction occurs:

The tendency to form calcium carbonate can be predicted qualitatively by

the Langelier Index, the Ryznar Index, or the Stiff and Davis Index, all

discussed below.

Calcium Sulfate (CaSO4) Scale

The most common form of calcium sulfate is gypsum (CaSO4 -2H20), which is

approximately 50 times more soluble than calcium carbonate at 100 F

(37.78 C). Above 100 F, the solubility of calcium sulfate decreases as the

water temperature increases.

Calcium sulfate should not present a scale problem in a cooling system using

proper blowdown procedures. The higher solubility of calcium sulfate is the

basis for scale control by pH adjustment with sulfuric acid.

Without exceeding the solubility limits of CACO,, sulfuric acid feed allows

the cooling tower to operate at higher cycles of concentration. This method

of scale control can lead to calcium sulfate deposition if excessive amounts

of sulfuric acid are used for pH control, or if the makeup water is high in

sulfates. The solubility product for calcium sulfate is 1.95 x 10-4.

To prevent calcium sulfate scale, the sum of the calcium concentration

(as CaCO3,) and the sulfate concentration (as CaCO3,) must be less than

1,500 and their product should be kept below 500,000. With chemical

treatment by a phosphonate, the sum of calcium (as CaCO3) and the sulfate

(as CaCO3) can be as high as 2,500, and their product should be less than

1,500,000.

Calcium Phosphate Scale

If polyphosphate is being used alone, or in combination with zinc or

zinc/chromate for corrosion protection, the polyphosphate ions may hydrolyze

and revert to orthophosphate ions. Orthophosphate levels can also be

contributed to by reversion of phosphonates or naturally from the makeup

water.

However, phosphate scales can occur if conditions are favorable for

tricalcium phosphate (Ca3(PO4)2) since the solubility product for calcium

phosphate is very small. Temperature, pH, calcium and orthophosphate

concentrations affect the formation of calcium phosphate. Calcium

orthophosphate scale is more insulating than calcium carbonate, and thus

causes rapid heat transfer loss.

Silica Scale

The solubility of silica in water is high, so pure silica scale (SiO2)

is rare in cooling systems. The maximum amount that can be maintained in

solution in cooling systems is approximately 200 ppm. The higher the pH,

the more silica will stay in solution (see Table below). Silica may

coprecipitate with iron, manganese, aluminum and magnesium hydroxides.

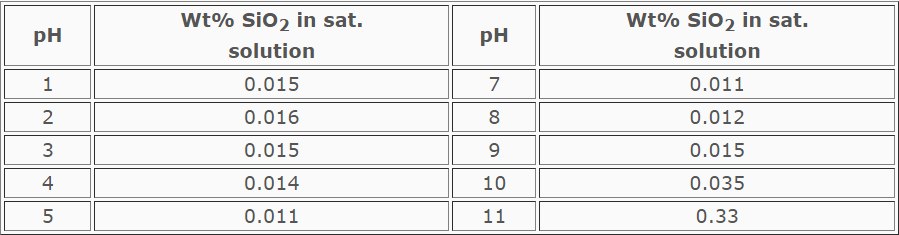

TABLE

Solubility of SiO2 at Various pH Levels

Magnesium Silicate Scale

Soluble silica reacts readily with cations to form various complex silicates.

If magnesium is present in high enough concentrations. magnesium silicate

scaling will occur at pH of 8.5. Deposition of magnesium silicate can be

prevented by keeping

1. (Mg ppm as CaCO3) x (SiO2 ppm) <35,000 ppm @ pH<7.5

2. (Mg ppm as CaCO3) + (SiO2 ppm) <17,000 ppm @ pH>7.5

or more generally by keeping silica levels <200 ppm in the recirculating

water. Magnesium silicates form by a two-step process: First, magnesium

hydroxide precipitates, then reacts with dissolved and colloidal silica to

form scale. Magnesium silicate scale occurs when the pH level is higher

than 7.8. Magnesium silicate does not occur if the pH of the circulating

water is lower than the pH of saturation of magnesium hydroxide. This pH

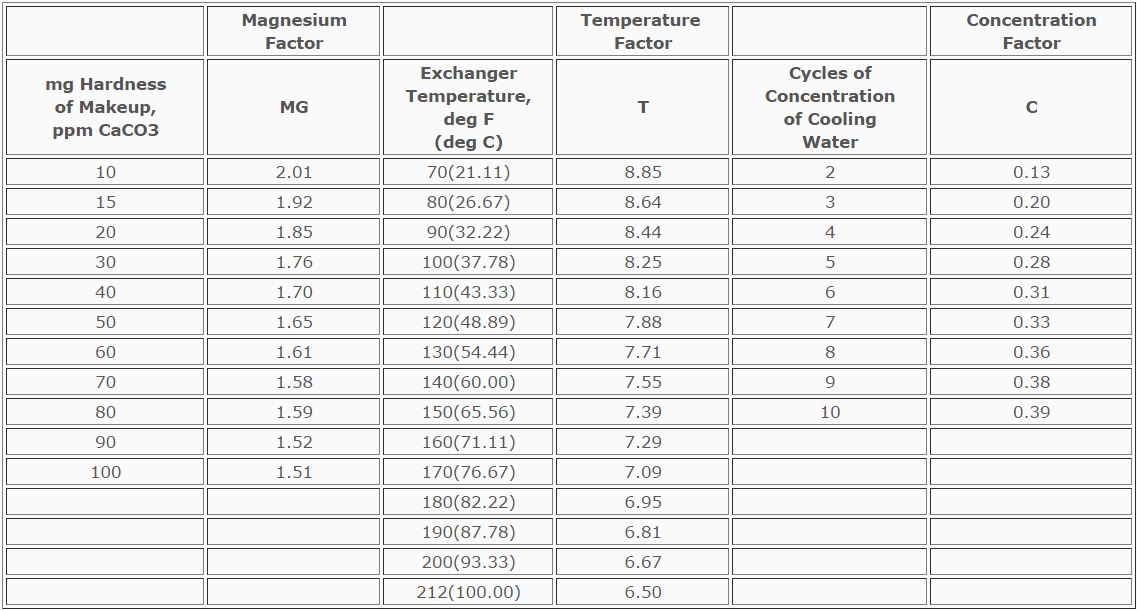

of saturation can be determined using the Table below, which is also helpful

in predicting the deposition of magnesium silicate.

TABLE

Prediction of Magnesium Silicate Scale Deposition

pHs = MG + T - C

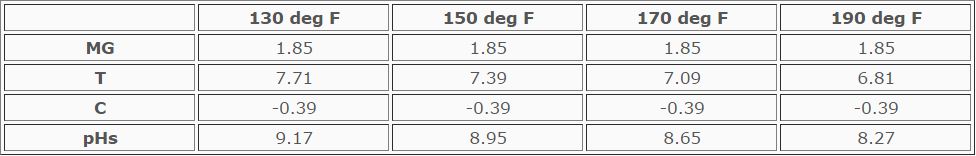

Example: MgH of makeup = 20 ppm, Cycles of concentration = 10 and pH of

circulating water = 8.7

Calculation of pHs at temperatures of 130, 150, 170, and 190 deg F:

This water would deposit magnesium silicate in coolers whose temperature

exceeds 170 deg F.

Iron-Based Scales

Iron exists in two states, Fe+2 and Fe+3. The chemistry of iron compounds

is considerably more complex than alkaline earth carbonate and sulfate

scale-forming materials. When these two oxidation states (Fe+2 and Fe+3)

of iron join with the same anion, the result is usually the formation of

compounds with significant differences in solubilities. Iron deposits

typically are in the form of Fe2O3, FeO, FeS, iron silicate, etc. Often

manganese is also detected in these deposits.

Iron fouling occurs as a result of corrosion processes throughout the system.

Thus, it is very important to implement a good corrosion control program.

Iron fouling sometimes occurs in cooling waters as a result of carryover

from clarifiers, where iron salts may be used as coagulants or where raw

water (such as well water) may be high in iron. Iron levels of 2 ppm or

greater in the recirculating water can be controlled through the use of

iron dispersants or deposit control agents. Use of an iron dispersant is

strongly recommended to avoid major equipment failure problems. In cooling

waters, Fe2O3 (hematite) and FeO are the most common iron deposits.

Magnetite (Fe3O4) is rarely found in cooling systems. Magnetite needs high

temperatures and/or anaerobic conditions. Most magnetite found in cooling

systems arrives via airborne or waterborne solids. If iron levels exceed

4-5 mg/l, mechanical or other means to remove iron should be strongly

considered, such as oxidation, aeration, coagulation, etc.

Zinc Phosphate and Zinc Hydroxide

Zinc hydroxide scale is normally found when pH exceeds 7.6 or when over-feed

of a zinc product occurs. Zinc hydroxide is a grayish-white precipitate.

With increasing pH, precipitate amounts increase. As pH is lowered below

7.0, zinc hydroxide will resolubilize. Above 140 deg F (60 deg C) it has

an inverse temperature solubility.. The most common methods to prevent

scale in cooling water systems are:

using scale inhibitors.

adjusting pH.

softening makeup water.

Estimating the Scale-Forming Tendency of Water

Scale forming and/or corrosive tendencies of water can be predicted

qualitatively by using the Langelier Index, Ryznar Solubility Index, or

the Stiff and Davis Index.

The Langelier Index:

For any given temperature and water composition,

one can calculate the tendency of the water to form calcium carbonate scale

by using the Langelier Index.

LSI = pH - pHs

where

pHs = pCa + palk + C

where

pHs = saturated pH

pCa = calcium hardness factor (expressed as ppm CACO3,)

palk = M alkalinity factor (expressed as ppm CACO3,)

C = total solids (expressed as ppm at the temperature of the water)

The Langelier Saturation Index (LSI) is defined as the difference between

the actual pH and the calculated saturated pH (pHs),

LSI = pH (actual) - pH (calculated)

LSI = pH - pHs

When the actual pH is equal to the saturated pH, the Langelier Saturation

Index is zero (LSI = 0 when pH = pHs). A saturation equilibrium exists.

There is no scale formation and corrosive attack is minimized.

When the actual pH is greater than the saturated pH, the Langelier

Saturation Index is positive (LSI when pH>pHs). Supersaturation of CACO3,

exists with respect to alkalinity and total solids at that temperature.

There is a tendency to form scale on heat transfer surfaces-

When the actual pH is less than the saturated pH, the Langelier Saturation

Index is negative (LSI = - when pH<pHs.). Any scale previously formed will

be dissolved. Corrosion of unprotected or bare metal will occur.

The Langelier Index does not tell whether scale will actually form, nor

how rapidly it will form.

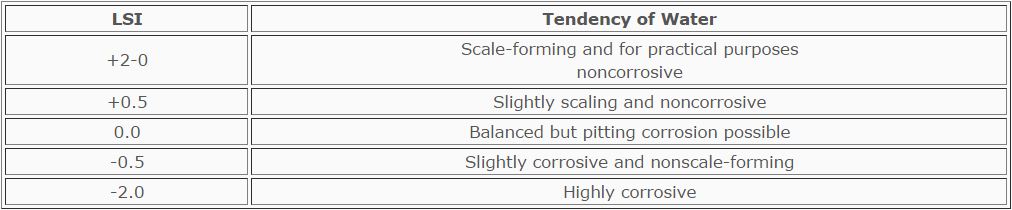

The prediction of water characteristics by LSI appears in the Table below:

TABLE

Prediction of Water Characteristics by the Langelier Index

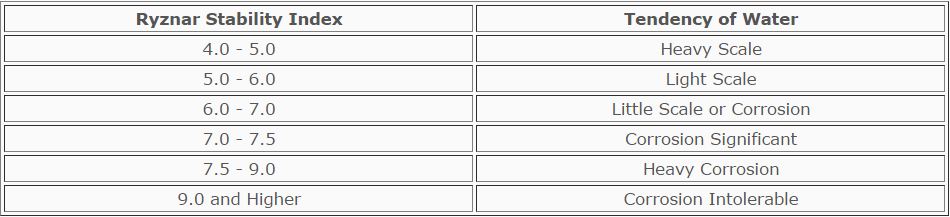

Ryznar Stability Index (RSI)

It is possible for a low-hardness water and a high-hardness water to have the same LSI value.

Using operational data and experience with scale and corrosion in a large

number of systems, Ryznar refined the Langelier Index to allow for a

distinction between two waters having the same Langelier Index. The

Ryznar equation is:

Ryznar Stability Index (RSI) = 2pHs - pH

The predictive nature of the Ryznar Index is shown in the Table below:

TABLE

Prediction of Water Characteristics by the Ryznar Index

The Stiff and Davis Index (SDI):

The Langelier Index has

been further modified by Stiff and Davis. Their index takes into account

the influence of high levels of dissolved solids on the solubility of

calcium carbonate. The SDI Index was developed for use in the oil field,

where highly saline waters or brines are produced. Where fresh water is

being used as makeup water for a cooling system, there is no need for the

refinements of the Stiff and Davis Index. However, as zero blowdown systems

become more common, as more and more reuse of water becomes necessary, and

as recovered wastewater is used in larger quantities as a makeup source, it

may become necessary to use the Stiff and Davis Index. The index is defined

as:

SDI = pH - pCa - pAlk - K

K = a constant based on the total ionic strength and temperature.

Methods of Scale Inhibition

Lime or Lime/Soda Softening

For cooling water applications, only partial lime or lime/soda softening is

economical. Often, sidestream lime softening is used as a supplement or

replacement for softening during external pretreatment prior to cooling

water applications. Occasionally, hot process lime or lime/soda softening

is used for silica removal in cooling water applications. In boiler

applications, however, hot or cold lime-soda softening is commonly used

for external treatment. This reaction is as follows:

2HCO3- + Ca(OH)2 --> CaCO3(s) + CO3-2 + 2H20

(M alkalinity)

Mg+2 + Ca(OH)2 --> Mg(OH)2(s) + Ca+2

Ca+2 + CO3-2 --> CaCO3(s)

Acid Treatment

The traditional method of calcium carbonate scale control is to reduce the

water's alkalinity sufficiently with sulfuric acid to create non-scaling

conditions.

Ca+2 + 2HCO3- + 2H++SO4-2 --> Ca+2+SO4-2 + 2CO2(g) + 2H20

The calcium bicarbonate is converted to volatile carbon dioxide and calcium

sulfate. Calcium sulfate is more soluble than calcium carbonate. The

cycles of concentration are limited by the solubility of calcium sulfate.

If the makeup water is high in sulfates, hydrochloric acid may be used to

reduce the alkalinity-, but chloride ions may cause problems because they

can penetrate oxide films, setting up local anodic cells and causing

corrosion.

Scale Inhibitors and Dispersants

The answer to the question of how scale inhibitors work is fraught with

complexities. One of the more logical explanations is that sub-

stoichiometric amounts of certain types of chemical additives can have

very marked effects on the growth rate of crystals deposited in a scaling

environment. These threshold inhibitors function by adsorbing onto the

growing crystals and distorting the lattice, which disrupts the crystal

growth process. The most commonly used threshold scale inhibitors are

inorganic polyphosphates, organophosphorous compounds, synthetic organic

dispersants and natural organic dispersants. Threshold treatment is the

term that describes the effective use of a scale inhibitor at concentrations

below the level required to sequester, or donate electrons to the metal ions

forming a water-soluble metal ion complex. The dispersant products are also

used to prevent scale formation by modifying the crystal structure of

the deposit-forming substance. This crystal distortion prevents deposition,

and the highly irregular stressed crystals tend to slough off as crystal

growth occurs.

Conventionally, scale inhibitors are classified as inorganic scale inhibitors

(such as sodium hexametaphosphate, sodium polyphosphate, sodium pyrophosphate)

or organic phosphorus compounds (such as the phosphate esters and

phosphonates). The inorganic phosphates used to treat scale contain

repeating oxygen/phosphorus bonds (-O-P-0-PO-P-). These bonds are highly

unstable in aqueous solutions, and as a result, they hydrolyze, or react

with water, and end up as ineffective orthophosphate. The hydrolysis of

such products is also referred to as reversion. Organic phosphorus

products are also subject to hydrolysis. The main factors that effect the

rate of reversion are pH and temperature. It is also influenced by

complexing cations, concentrations, holding time index, ionic environment

in the solution, and other factors. Environmental restrictions imposed upon

the industry have made organic treatments almost a necessity. The following

discussion about organic scale inhibitors and dispersants will be useful in

understanding the types of products.

Phosphate Esters

A typical phosphate ester functional group may be represented as follows:

O

||

R - C H 2 - O - P - O H

|

O H

Phosphate esters are less likely to hydrolyze than inorganic polyphosphates

and more likely to hydrolyze than phosphonates. They exhibit varying degrees

of threshold scale inhibitor properties. In fact, some phosphate esters are

ineffective as scale inhibitors.

Phosphonates

A typical phosphonate has the following structure:

O

||

R - C H 2 - P - O -

|

O -

This structure with C-P-0 bonding is more stable to hydrolysis than the

phosphate ester.

A variety of amino methylene phosphonic acids and their salts are available

commercially as scale inhibitors. They are effective inhibitors for both

calcium sulfate and calcium carbonate scale at very low threshold

concentrations. Non-nitrogen-containing phosphonic acids are widely used

because they are more compatible with chlorine than the aminomethylene

phosphonic acids. Phosphonates are believed to inhibit scale formation by

being adsorbed on active crystal growth sites, where they decrease the

crystal growth rate and decrease the nucleation rate. A number of blends

or combination products that incorporate low molecular weight dispersant

polymers with phosphonates are available. Phosphonates containing nitrogen

are good for iron control because the close proximity of the nitrogens allows

for formation of strong five-membered ring metal complexes with iron. The

structure of a typical phosphonate is as follows:

HEDPA

OH OH OH

| | |

HO - P - C - P - OH

|| | ||

O CH3 O

AMP

/C H 2 P O 3 H

N - C H 2 P O 3 H

C H 2 P O 3 H

Synthetic Polymeric Dispersants

A large number of synthetic polymers are used as scale inhibitors and as

dispersants. Most of the synthetic polymers have a molecular weight

below 50,000 and are polymers of acrylic acid, acrylamide, methacrylic acid,

maleic acid, maleic anhydride, styrene maleic blends and maleics

(methylvinyl ether), etc. The effectiveness of the polymer decreases as the

chain length increases. A length of about 10-15 repeating units is best.

At this molecular weight, adsorption is maximized without causing bridging,

and dispersion is most efficient. Synthetic polymers such as polyacrylates

are believed to inhibit scale deposition by adsorption on growing crystals.

This is followed by both crystal structure modification and by a charge

repulsion mechanism of negative charges, which leads to destabilization of

the crystallites. Polymers are also used for iron control.

Natural Organic Polymers - Lignosulfonates

Lignosulfonate derivatives come from pulsing operations where wood is

sulfonated at high temperatures to remove the lignin binder from the

cellulose by forming a water-soluble polymer. This polymer is a highly

complex natural derivative and its structure is not well defined.

Lignosulfonates are classified as anionic polyelectrolytes. Those used

as dispersants usually have a molecular weight between 1,000 and 10,000.

Lignosulfonates are usually poor scale inhibitors. However, these organic

polymers are reported to be good dispersants for calcium phosphate,

suspended matter and iron oxides. Lignosulfonates function as dispersants

by limiting attractive forces between particles, thereby reducing

sedimentation.

Inorganic Polyphosphates

Polyphosphates are commonly used in once-through and municipal applications

to minimize scaling and corrosion at dosages of 1 to 5 mg/l of polyphosphate

as PO4. Thus, polyphosphates function as threshold treatments because they

are effective at dosages much less than those stoichiometrically required to

react with calcium, magnesium or iron. The repeating (P-0-P) structure is

characteristic of inorganic polyphosphates.

Although the advantages of low cost and threshold activity are attractive

for the use of polyphosphates, they are ineffective as scale inhibitors at

high levels of calcium. High iron and manganese levels can restrict the

effectiveness of polyphosphates by forming stoichiometric iron-polyphosphate

complexes that hinder the performance of polyphosphates as inhibitors for

calcium and magnesium deposits. In addition, polyphosphates act as nutrients

for bacteria. As a result, higher biocide dosages may be required if

polyphosphates are used for scale or corrosion control.

Surfactants

Surfactants are used in cooling systems either to emulsify or disperse

hydrocarbons, or to penetrate biomasses. Their primary purpose is to

prevent hydrocarbon and microbial deposition on heat transfer surfaces.

Surfactants also aid in de-oiling surfaces and keeping suspended solids,

including biomass, dispersed. Surfactant types are generally classified

as anionic, cationic, nonionic and amphoteric.

Surfactants work in one of two ways. If they are nonionic or amphoteric,

they reduce surface tension or interfacial tension at liquid-solid,

liquid-air, liquid-liquid and solid-air interfaces. This changes the

wetting characteristics of solids, making them either water-wet or oil-wet.

If the surfactants are anionic or cationic, they work by charge enhancing

the solids, either oil or biomass, and forcing those solids to repel one

another. This keeps the solids dispersed in the system water for later

removal. Reduction of interfacial tension is also achieved through the

use of anionic and cationic surfactants.

Problems Caused by Scale or Fouling Deposits in

Cooling Systems

Reduced or uneven heat transfer

Unexpected equipment shutdown - loss of production

Shortened equipment life

Increased pumping costs

Equipment corrosion

Product loss due to ineffective cooling

Increased product cost due to above factors

Profit Loss